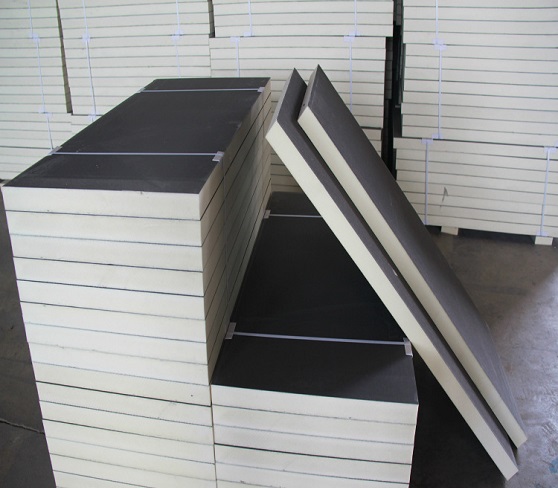

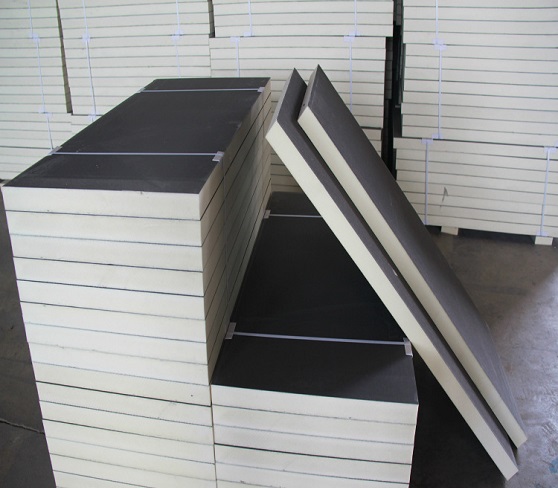

Rigid polyurethane composite material is divided into two components: isocyanate and polyether: commonly known as black and white. The rigid polyurethane foam with an independent closed-cell structure is produced by proportionally stirring and mixing. It is an ideal organic low-temperature insulation material with small thermal conductivity, energy-saving and shock-proof, and strong adaptability. It can be pre-fabricated or sprayed on-site pouring moulding and widely used in refineries, chemical plants, ethylene chemical industry, cold storage and single refrigeration. Central air-conditioning, refrigerators and construction industry heat preservation and insulation. With the promotion of building energy saving in our country, polyurethane foam insulation system has been widely used in domestic thermal insulation field because of its good thermal insulation performance, rapid construction and reliable performance.

1. Main Contents and Scope of Application

Technical requirements, test methods and inspection rules for rigid polyurethane foams:

This standard is applicable to rigid polyurethane foams formed by spraying and pouring after full mixing of isocyanate and composite polyether.

2. Technical Requirements

The technical requirements of products shall be in accordance with the enterprise standard Q/FDF001-2000.

2. Technical requirements of rigid polyurethane foam composite polyether:

Physical Properties of Composite Polyether

Appearance: Light yellow or brown transparent liquid

Viscosity: (25 C) 200-400 (Mpa. S)

Hydroxyl value: 350-450 (mgkoh/g)

水份:<0.3%

Storage period: 6 months (15-25 C)

3. Use methods:

★Casting type

Component A and PAPI (Component B) are mixed according to the required weight ratio (A/B=1/1). Mechanical stirring time is 10-20 seconds, rotating speed is 1400 rpm. After stirring uniformly, the mould is ripened immediately. The optimum temperature of the mould is 30-40 degrees Celsius, and the ambient temperature is 15-20 degrees Celsius. (Feeding can be increased according to the density of the product)

★Spray type

The suitable temperature range for spraying foaming is 15-35 degrees Celsius, and the suitable ambient temperature is 15-30 degrees Celsius. When the ambient temperature is low, it should be heated and the composite material should not exceed 27 degrees Celsius. The sprayed surface should be rust-free, oil-free, dust-free and dry. Each time the composite material is used, it should be stirred before tightening the lid of the barrel to prevent dampness.

Storage and Safety Operation of Polyurethane Composite Polyether and Isocyanate

one. storage

Isocyanate (commonly known as black material) and composite polyether (commonly known as white material) must be stored in sealed containers to isolate air and prevent moisture absorption.

Isocyanate and composite polyether barrel should not be exposed to the sun, must be away from the heat source, placed in a cool and dry place, barrel if placed upright, barrel cover must not accumulate water! If the whole barrel material can not be used up at one time, the barrel cover must be tightened immediately after each use to prevent water vapor and impurities from entering the barrel and affecting the quality. If more than two brands of polyethers are used, they should be stacked in different grades and marked clearly. The storage time of the composite polyether with common flame retardant should not be too long. It must be used on the day of preparation, otherwise it will easily deteriorate and affect the foaming quality. For further information, please contact our technical service department.

Two, operation

Protective glasses, work clothes and work caps must be worn when operating isocyanate and composite polyether, and clean rubber gloves should be worn when operating isocyanate. The working environment must be well ventilated and clean. When the ambient temperature is high, the foaming agent in the composite polyether will partly vaporize and produce pressure, so the exhaust cap should be opened before the barrel cap is opened. When the foam is flame-retardant (Note: self extinguishing), additive flame retardants can be used. The addition of ordinary flame retardants is 15 to 20% of the weight of the white material, and the flame retardant must be evenly mixed in white material before foaming.

The proportion of black and white material should refer to the loose page of technical data of combined polyether of relevant models. The customers who use flame retardants should pay attention to calculating the proportion of white material after adding flame retardants. If the proportion of black and white material is 1:1 and the ratio of 100 kg white material to 15 kg flame retardant is required, the amount of black material used is 115 kg.

When manual foaming operation is done, proportionally weigh the black and white materials proportionally and pour them into the container at the same time. After stirring for 8~10 seconds with more than 2000 revolutions / minutes, then pour into the mold and foam. The release time depends on the requirements of the products and the thickness of the foam.

Three, safety

When the skin is exposed to the combined polyether, wash it with soap and water.

When operating isocyanate, special attention should be paid to it, because it has a certain irritation, do not inhale its steam, and do not splash on the skin and eyes.

If it splashes on the skin and eyes, it must be wiped off immediately with medical cotton, then rinsed with a large amount of water for 15 minutes, then rinsed with soap or alcohol. If it is still serious, it should be treated in the hospital. Once a large area of isocyanate spraying occurs, sand and sawdust are used to cover the ground, and then a large amount of water is used to wash the ground. When clothes are contaminated with isocyanate, they must be treated with a solution containing 50% ethanol, 45% water and 5% concentrated ammonia, and then washed with soap.

Note: Pay attention to storage methods and safe operation.

Home

Home