Polyester fibers are the textile fibers with the largest output and the largest variety in China. However, China's new polyester PTT (poly (1,3-propylene terephthalate) chips have long relied on imports, and its key technology of polymerization has been monopolized by DuPont and Shell. The key technology and industrialization of PTT and in-situ functionalized PET polymerization and the preparation of its composite fibers were completed by Shenghong Holding Group Co., Ltd., Beijing Garment College, Jiangsu Perch Science and Technology Development Co., Ltd. The technology of multi-functional polyester industrialization with large capacity was initiated, and the product innovation was driven by the innovation of raw materials to develop the polyester industry. A new model was created to realize the localization of high-quality textiles from the source of polymers to the end products, thus winning the second prize of National Science and Technology Progress in 2015.

Mei Feng, chief engineer of Shenghong Stock Company, told reporters that the project relies on the preparation and application technology of high comfort serialized polyester fibers of the national science and technology support plan project. After years of hard work, four breakthroughs in core technology were finally achieved, which not only filled the gaps in new polyester and composite functional fibers in China, but also made our country a better place. In this field, we are at the forefront of the world.

Firstly, the project breaks through the complete technology of PTT and modified PTT (MDPTT) polymerization, by-product treatment and recovery, independently develops titanium-tin composite catalyst and new stabilizer, designs five-vessel process of back-flow esterification and low-temperature polycondensation, realizes high efficiency, energy saving and flexible copolymerization. The sustained-release crystallization granulation technology developed by the project can save 27%~35% energy. The technology of cyclic dimer depolymerization, separation and recovery not only reduces the material consumption, but also realizes the harmless treatment of acrolein and allyl alcohol.

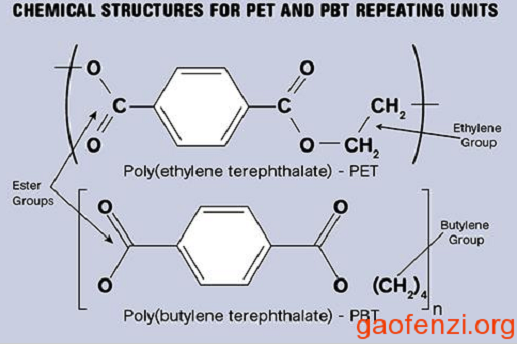

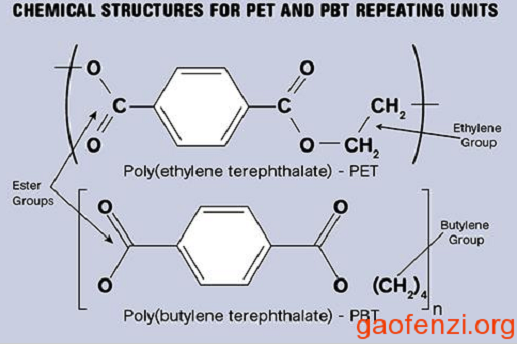

Secondly, the project has tackled the key technologies of large-capacity multi-functional PET (MFPET) and large-capacity polymerization and melt direct spinning, and created a multi-functional technology with organic (P22) / inorganic (ATO) antistatic agent, organic (UV234) / inorganic (titanium dioxide) antiultraviolet agent synergy, moisture absorbent monomer and pore-forming agent composite, and independently designed swirl flow homogenization and anti-condensation. MFPET was successfully prepared by equipment, electrostatic eliminating device, esterification in three kettles, stirring polycondensation kettle with double squirrel cages and high polishing low temperature melt conveying system.

Thirdly, the project designs special spinning key equipment and develops a complete set of forming technology of MDPTT, MFPET and high viscosity difference PTT (MDPTT)/MFPET fibers to produce moisture absorption, elasticity, anti-static, anti-ultraviolet and other multi-functional composite polyester fibers.

Finally, the project successfully developed a complete set of technologies for the synthesis of Thermo-wet comfortable polyester and its fiber manufacturing, which solved the problems of functional powder hyperdispersion, esterification, polycondensation rate, molecular structure and relative molecular quality control, and developed the key technologies of multi-functional polyester continuous polymerization and melt direct spinning, and produced different functional combinations. Hot and wet comfort polyester filament, staple fibers and their fabrics.

According to Meifeng, the project has been successfully industrialized in Shenghong Holding Group. The first PTT continuous polymerization production line with independent intellectual property rights, 250,000 tons/year full extinction multifunctional polyester polymerization and melt direct spinning production line, and 50,000 tons/year MDPTT/MEPET elastic controllable series multifunctional polyester fiber production line have been built successively. Production line. The output and market share of MDPTT, MEPET and their composite fibers produced by the project rank first in China. The differential rate of polyester fibers is over 80%. The total sales revenue of the project is nearly 10 billion yuan. The products are exported to Europe, America, Japan, Korea and other countries and regions.

The construction of 30,000 tons/year PTT/MDPTT polymerization unit has made Shenghong the third enterprise with PTT polymerization technology after Dupont and Shell, and the construction of 250,000 tons/year large capacity multi-functional MFPET melt direct spinning polyester fiber production unit has realized the expansion of multi-functional polyester to fine denier, ultra-fine denier fibers and profiled cross-section fibers. Shenghong has become the world's largest manufacturer of melt direct spinning multi-functional polyester filament; the construction of 50,000 tons/year elastic comfort series polyester fiber production line has realized the preparation of safe, comfortable and multi-functional fibers, fabrics and clothing from self-synthesized new functional polyester, and formed independent intellectual property rights.

Industry experts believe that the successful R&D and industrialization of the project has promoted the technological progress of polyester and the upgrading of its products, met people's demand for high-grade new fabrics, brought new economic growth points for enterprises, and enhanced the international market competitiveness of China's chemical fiber fabrics.

The thermal-wet comfortable polyester filaments, staple fibers and their fabrics produced by the project have the highest output and market share in China.

label:

Home

Home